Title: Minimizing Excessive Soil Compaction during Construction Utilities on Wet Soil

(Phase-I Project Report Sponsored by Iowa State Association of Counties)

Authors: Mehari Z. Tekeste (a), Adewale S. Sedara (a), Mark H. Hanna (b)

(a) Associate Professor, Agricultural and Biosystems Engineering (ABE), Iowa State University (ISU), 2331 Elings Hall, Ames, Iowa, 50011. (b) Retired Extension Agricultural Engineer, ABE, ISU. Corresponding Author’s email: mtekeste@iastate.edu

Background and Objectives: Heavy-axle load machinery operation in the right-of-way (ROW) on wet soil conditions creates excessive soil compaction, negatively impacting soil health and crop productivity. Working on wet soil conditions and mixing are the major factors affecting the soil health properties during construction. Recent underground construction utilities, for example, the DAPL project installed a 347- mile (558 km) pipeline in Iowa with approximately 57,000 tons per mile of topsoil removed and backfilled to the ROW. New CO2 sequestration pipeline projects have been predicted to install up to 1580 miles of mileage in Iowa and potentially remove and backfill 90,000 tons of topsoil. In addition to the underground pipeline installation for CO2 sequestration and crude oil transfer, renewable solar and wind projects demand construction activities on highly productive soils in the corn-soybean region of the United States. Limited scientific studies have been conducted that quantify the in-situ soil wetness of agricultural soils impacted by utility-related construction activities that define the relationship of soil moisture to soil-bearing capacity under heavy-axle loads. The study aimed to develop soil compaction management practices to avoid excessive soil compaction and accelerate farmland productivity from pre-construction activities to normal food production. The proposed study developed methods to determine field soil wetness and establish a relationship between in-situ soil water, precipitation from real-time data, and the degree of soil bearing capacity for minimizing heavy-load-induced rutting.

The specific objective of the study was to conduct research on soil compaction, the results of which may be used by Iowa Association of Counties (ISAC) to inform practices regarding the restoration of agricultural land damaged by pipeline construction activities. The study was designed to sample soil cores in the field at soil wetness conditions at soil bearing capacity to support nominal ground contact pressure of 15 PSI per rear drive tire of a two-wheel drive (2WD) tractor equipped with in-situ ISU Giddings core sampler. Soil moisture content was measured and classified as “field capacity soil condition allowing to support bearing capacity at 15 PSI ground contact pressure from rear-axle drive wheel loading”. Allowable soil bearing capacity was considered sufficient for the field soil wetness with minimum rut formed (soil rut penetrated not to exceed the lug of the drive wheel of the 2WD tractor equipped with 16.9-38 bias ply tires with axle load of 9,930 lbs.).

Minimally disturbed soil core samples were collected using the 2WD tractor equipped with an in-situ ISU Gidding core sampler on soils representing four soil drainage classes in Iowa. Farms with dominant soil series of (1) Okoboji silty loam soil series (Fine, smectitic, mesic Cumulic Vertic Endoaquolls), (2) Clarion loam series (Fine-loamy, mixed, superactive, mesic Typic Hapludolls), (3) Nicollet loam series (Fine-loamy, mixed, superactive, mesic Aquic Hapludolls), (4) Hanlon fine sandy loam series (Coarse-loamy, mixed, superactive, mesic Cumulic Hapludolls), and (5) Monona silty clay loam series (Fine-silty, mixed, superactive, mesic Typic Hapludolls) were selected for their proximity to the SMDL and assumed to represent different soil drainage classes. Soil core samples in a metallic cylinder (7.62 cm (3 in.) diameter and 5.08 cm (2 in.) long) were brought to saturated soil condition using a fine-sandbox built at the Soil Machine Dynamics Laboratory (SDML) at ISU. The saturated soil core samples were gravity drained in laboratory scale setup to estimate the soil moisture content during the saturation-gravity drainage-field soil wetness condition. Data on initial soil bulk density, soil moisture content at the field wetness, and soil moisture content every eight hours during gravity-driven drainage were collected for the five soil types.

The laboratory experiment determined the number of days to drain the saturated soil by gravity-driven drainage and relative to the moisture content at field soil wetness for allowable bearing capacity, estimating the expected number of days of field sampled soil from saturated soil condition to field soil wetness for trafficking without excessive soil rutting. Using the soil moisture data and the days to drain from saturated to field “soil wetness”, the five soil types were classified into three soil wetness classes: well-drained soil wetness (Fine Sandy Loam, 14% soil moisture content on a dry basis), moderately-drained soil wetness (Silty Clay Loam, 19% soil moisture content on dry basis) and poorly-drained soil wetness (Silty Clay Loam to Loam, 22% soil moisture content on dry basis). On average, among all the soil wetness classes, three-day indoor gravity drainage was elapsed from the saturated state to the field soil wetness, allowing soil bearing capacity of 15 PSI ground contact pressure.

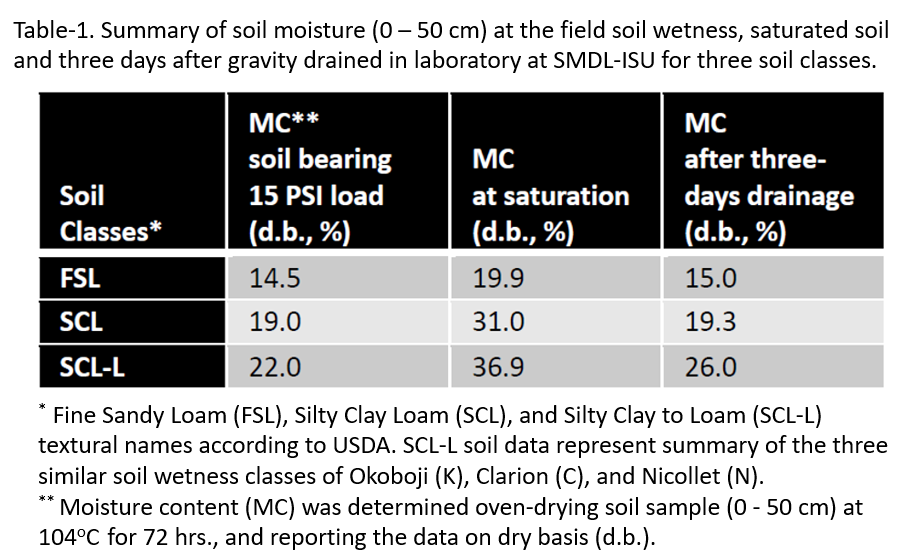

A summary of the soil moisture content at the field soil wetness, saturated conditions, and three days after drained in laboratory conditions from the three soil classes, and top soil depth (0 – 50 cm (20-in.)) are shown in table 1. For the well-drained and moderately drained soil wetness, the differences in moisture content at the field soil wetness (soil bearing 15 PSI load), and the moisture contents after three-day drainage in the SMDL soil box were less than 1%. In the relatively poor drained soil classes (SCL-L), the soil retained high moisture even after three days of drainage (4% greater than the MC at the field soil wetness), which could create potential excessive rutting.

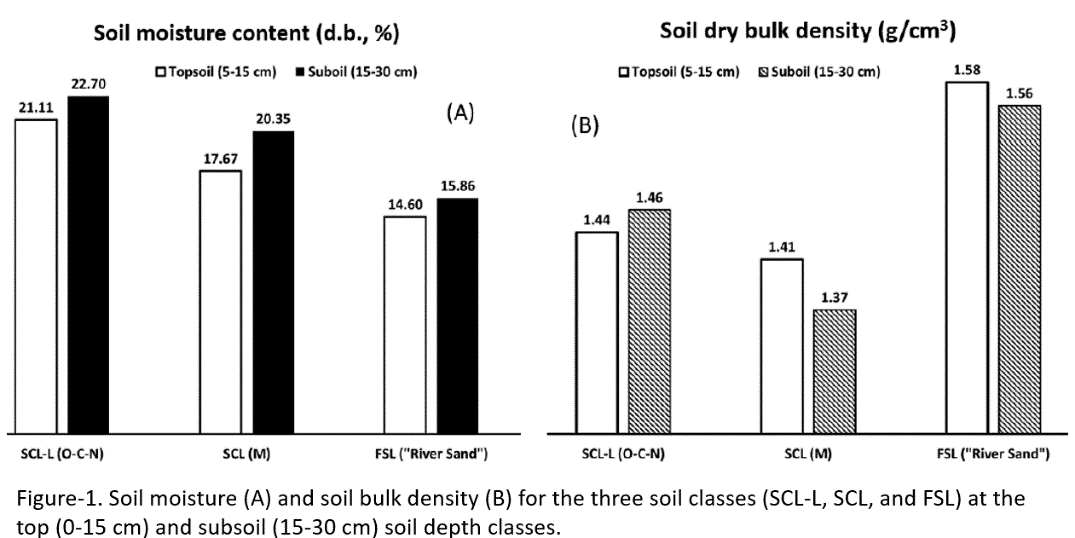

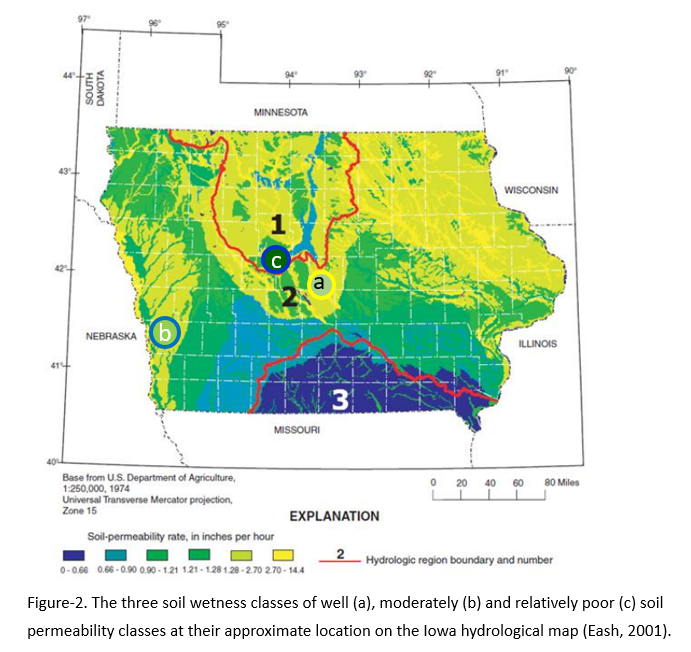

Figure 1 shows the soil moisture content and initial soil bulk density at the field wetness and soil bearing capacity supporting the 15 PSI ground contact pressure. In both the top and subsoil depths (Fig. 1b), the magnitude of soil bulk density from all the soil classes had values less than ROW heavy-axle induced mean soil bulk density of 1.67 g/cm3 (at 96% of Proctor compaction density), measured year-one after pipeline installation (Tekeste et al., 2019). The initial soil bulk density data could be used as a baseline to monitor residual soil compaction after construction or post-deep tillage management in ROW. According to Eash (2001), the well-drained soil wetness (FSL), moderately drained soil wetness (SCL) and poorly-drained soil wetness (SCL-L) classes studied were found in the well, moderate and relatively low soil permeability classes, respectively. Considering this, researchers conclude that more soil sampling is needed from moderate-to-well (Northeastern of region 2) and poor (region 3) soil permeability classes of the Iowa hydrological map to cover soil wetness classes (Fig. 2).

Conclusion: A method was developed to determine soil wetness related to ROW heavy-axle machinery operation during underground utility construction activities on farm soils and manage the soil wetness to minimize excessive soil rut depth. Using the SMDL-ISU soil wetness procedure, out of five crop field samples, three soil wetness classes were defined and categorized based on the Iowa hydrological map and their relationships to field soil bearing capacity of 15 PSI ground pressure loading. The method developed at the SMDL-ISU for defining the field soil wetness allowing soil bearing capacity at rut depth less than the lugs of 16.9-38 bias ply tires (4,965 lbs. Per tire) and soil moisture saturation to gravity drained findings could be implemented for different soil types. The method could also be used to develop a field technical support guide for field soil wetness measurement by measuring in-situ soil moisture, accounting for rainfall events and climatic field conditions (wind, evapotranspiration, etc.), and measuring vehicle ground pressure simulated plate loading and sinkage rut depth relationship using a newly developed soil sinkage measurement apparatus at the SMDL-ISU.

Future research is needed to perform soil sampling on two soil series classes from the poor soil permeability region of the Iowa hydrological map and determine their soil wetness classes. With the two new soil series sampling, all the soil drainage classes in Iowa will be included in the soil wetness classification for the soil compaction management plan on the underground construction utilities impacted sites in Iowa. A newly proposed study needs to include the development of in-situ soil rut measurement and soil moisture monitoring to develop guidelines for inspectors and land managers for monitoring wet soil classes and preventing excessive soil rutting.

Acknowledgments

The authors acknowledge the funding from Iowa State Association of Counties (ISAC), and Nick Palmersheim, Agricultural Assistant at Agricultural and Biosystems Engineering (ABE) at Iowa State University for supporting soil sampling.

References

Eash, D.A., 2001. Techniques for Estimating Flood-Frequencies Discharges for Streams in Iowa. Iowa City, Iowa: Iowa Department of Transportation and the Iowa Highway Research Board.

Tekeste, M. Z., Hanna, H. M., Neideigh, E. R., & Guillemette A., 2019. Pipeline right-of-way construction activities impact on deep soil compaction. Soil Use Management, 35, 293–302. https://doi.org/10.1111/ sum.12489